The Present and Future of Recycling in Phoenix

Chart above courtesy of Waste Management

Maximizing Resources – Waste Management’s Green Vision for Phoenix

In a city where the desert environment demands conscious use of natural resources, Waste Management has emerged as a critical player in turning waste into opportunity. Their operations in Phoenix exemplify a cutting-edge approach to environmental stewardship—sorting and recycling garbage in ways that help the city minimize its ecological footprint while tapping into the hidden potential of everyday waste.

Sorting for Sustainability

At the heart of Waste Management’s efforts in Phoenix is an advanced sorting process that transforms the way the city handles its trash. Their Material Recovery Facility (MRF) employs state-of-the-art technology to automatically separate recyclables from waste, ensuring that valuable materials like paper, plastic, metal, and glass are diverted from landfills. Phoenix residents contribute by sorting their waste at the curb, but Waste Management takes it further, employing a combination of manual and mechanical processes to ensure that no resource goes unnoticed.

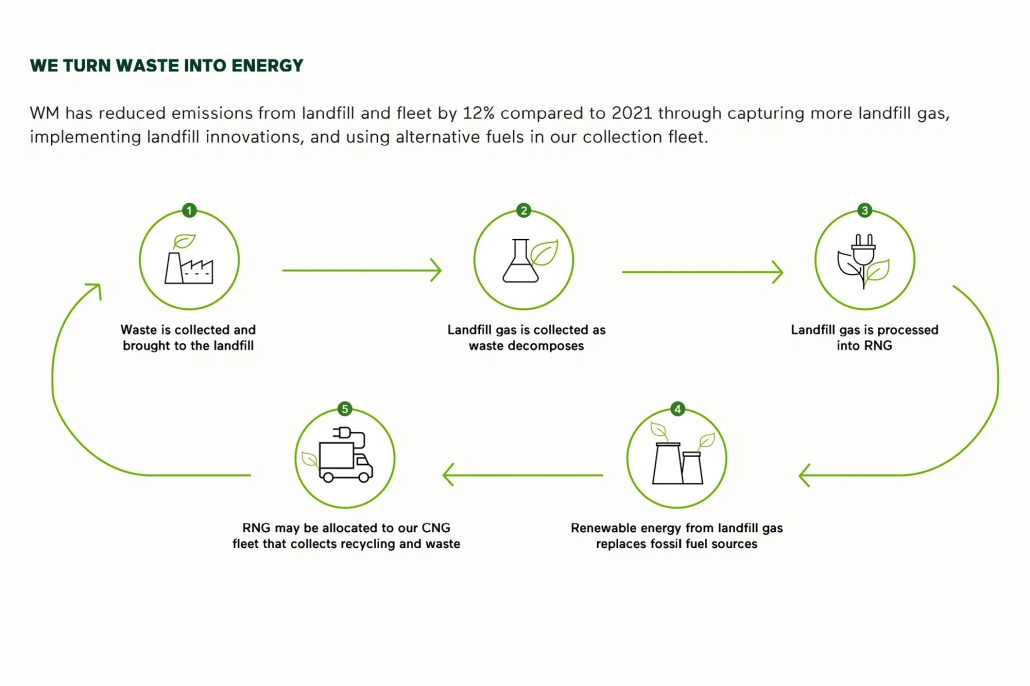

This comprehensive approach allows Waste Management to extract maximum value from every piece of garbage. Organic materials, for example, are sent to composting facilities to enrich the desert soil, while non-recyclable materials may be processed to produce renewable energy through waste-to-energy initiatives. It’s a system designed to close the loop on waste and extend the life cycle of natural resources.

The Future of Recycling in Phoenix

Phoenix, a rapidly growing city, produces an enormous amount of waste. Waste Management’s commitment to sustainability is vital to ensuring that future generations have access to the region’s natural beauty and resources. Their efforts to educate residents on responsible waste disposal—combined with technological innovations that allow them to sort waste more effectively—are setting a national standard for urban recycling programs.

Not only does this reduce the volume of material heading to landfills, but it also significantly lowers carbon emissions, conserves water, and supports the local economy by creating jobs in the green sector. Waste Management’s work in Phoenix proves that a forward-thinking, sustainable approach to waste can benefit both the community and the planet.

Turning Waste into a Resource

What might seem like a discarded soda can or food container to many is, in fact, an opportunity for Waste Management. Every material that enters their system is evaluated for its potential to be recycled, repurposed, or converted into energy. Phoenix’s desert climate and limited natural resources make it all the more crucial to extract value from the waste stream.

By recovering and recycling materials, Waste Management reduces the need for raw resources like oil, water, and trees, conserving the very elements that define life in the desert. This process also aligns with Phoenix’s broader sustainability goals, ensuring that the city grows responsibly while protecting its fragile ecosystem.

A Green Path Forward

As Phoenix continues to expand, Waste Management’s leadership in recycling and resource recovery will play a critical role in preserving the city’s natural environment. Their efforts highlight the power of innovation and community cooperation in turning waste into a valuable resource.

A Deeper Dive Into The Sorting Process

Waste Management’s sorting process is a sophisticated, multi-step operation designed to maximize the recovery of recyclable materials while minimizing what ends up in landfills. Here’s a detailed breakdown of how the sorting process typically works, specifically in Phoenix, AZ:

1. Collection and Transportation

It all begins with the collection of waste from residential, commercial, and industrial sources. In Phoenix, Waste Management uses specialized trucks to gather recyclable materials, organic waste, and non-recyclable garbage, often in separate bins provided to residents and businesses. These trucks transport the waste to a Material Recovery Facility (MRF) for sorting.

2. Pre-Sorting

Upon arrival at the MRF, the waste is first subjected to a pre-sorting phase. This initial step involves manually removing large, non-recyclable, or hazardous items (like plastic bags, textiles, or electronics) that could damage sorting equipment. Workers may also remove any contaminants that could interfere with the recycling process.

3. Mechanical Sorting

Once pre-sorting is complete, the remaining materials enter a series of highly automated, mechanical sorting systems that use various technologies to separate recyclables based on their properties.

Trommel Screens: These large, rotating drums are used to sift materials by size. Smaller items like glass shards or dirt fall through holes in the screens, while larger items like cardboard, plastic bottles, and cans continue on for further processing.

Air Classifiers: Air streams are used to separate lighter materials, such as paper and plastic, from heavier items like metals and glass. The lighter materials are blown into a separate area for further processing, while the heavier ones are sorted downstream.

4. Optical Sorting

Next, Waste Management employs optical sorters, which use infrared sensors to identify different types of plastics based on their chemical composition. These machines can precisely sort materials like PET (from water bottles) and HDPE (from detergent bottles), ensuring that each type of plastic is separated for recycling.

Near-Infrared (NIR) Technology: NIR scanners detect specific wavelengths reflected by different plastics, allowing for high-speed sorting of multiple plastic types in seconds.

Color Sorters: Some optical sorters also use color recognition to separate materials, like distinguishing between clear, green, or brown glass for recycling.

5. Magnetic Separation

For metal separation, the facility uses powerful magnets to extract ferrous metals like steel from the waste stream. This method ensures that metal cans, appliances, and other steel-based materials are pulled away for recycling.

Eddy Current Separators: Non-ferrous metals (like aluminum and copper) are separated using an eddy current system, which creates a magnetic field that repels non-magnetic metals, pushing them into a separate bin.

6. Glass Separation

Glass is typically separated early in the sorting process using trommel screens or vibrating machines that break it into small pieces. These glass shards are directed to a specialized area for further processing, where they are cleaned and sorted by color before being sent to manufacturers to make new glass products.

7. Final Quality Control

After all mechanical and optical sorting steps, the separated materials are subjected to quality control checks, often involving manual inspection. Workers ensure that only clean, uncontaminated recyclables make it through. Any items that were improperly sorted or missed by machines are removed at this stage.

8. Baling and Shipping

Once materials are fully sorted, they are compacted into bales—large, condensed blocks of recyclables like paper, plastic, metal, or cardboard. These bales are then sold to manufacturers who use the recycled materials to produce new products. For example, paper might be recycled into packaging, and plastics into new bottles.

9. Organic Waste and Energy Recovery

For organic waste, such as food scraps and yard waste, Waste Management in Phoenix often diverts these materials to composting facilities or anaerobic digesters. Composting turns organic waste into nutrient-rich soil for landscaping or agriculture, while anaerobic digestion can convert waste into bio-gas, a renewable energy source.

Non-recyclable waste that cannot be processed any further is often used in waste-to-energy facilities, where it’s incinerated to generate electricity, further reducing the need for landfills.

This advanced sorting process enables Waste Management to maximize the recovery of valuable materials, minimize contamination, and significantly reduce the amount of waste sent to landfills. Through this system, they contribute to a circular economy where more resources are reused and less is wasted.

Waste Management

Waste Management